VelinXtech

Precision Engineering at its Finest

With a team of highly skilled engineers, technicians, and industry experts, VelinxTech brings unparalleled expertise to every project.

Your Vision, Our Expertise - Unmatched CNC Craftsmanship

Driven by the passion for engineering and manufacturing excellence.our state-of-the-art facility houses a team of skilled engineers, technicians, and artisans, equipped with cutting-edge technologies to deliver top-notch products and services.

CNC Machining Services

Our expertise in CNC operation allows us to craft precise and intricate components to meet your unique specifications. With a focus on efficiency and accuracy, we streamline the production process, saving you time and resources.

- CNC milling

- CNC turning

- injection molding

- Casting

- Products Finishing

Custom Metal Parts Sourcing

we understand that custom metal parts is critical for your success. With a comprehensive network of trusted suppliers and manufacturers, we take the burden off yours, ensuring high-quality components delivered to your doorstep.

Why Choose Us

Advanced Manufacturing Technologies –We leverage cutting-edge technologies, including CNC machining, 3D printing, and injection molding, to deliver superior manufacturing results. Our commitment to staying at the forefront of technological advancements enables us to offer innovative solutions that meet your specific requirements.

Experienced Team

Our team of skilled engineers, technicians, and project managers brings years of industry expertise and knowledge to every project. We collaborate closely with you to understand your unique needs and provide comprehensive support throughout the manufacturing process.

Quality Assurance

Quality is at the core of everything we do. With stringent quality control measures, rigorous testing, and meticulous attention to detail, we ensure that every product we deliver meets the highest standards of precision, functionality, and durability.

Client Focused

At VelinxTech, we prioritize customer satisfaction. We strive to build long-term partnerships by delivering exceptional service, prompt communication, and personalized solutions that address your manufacturing challenges effectively.

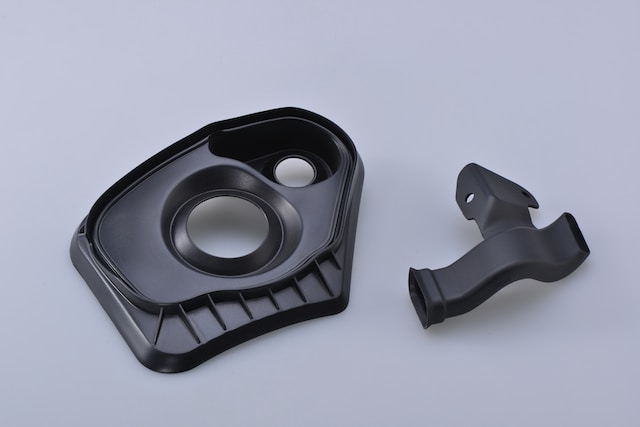

Casting

With our cutting-edge mold making and casting capabilities, we offer custom solutions for complex geometries and intricate designs.

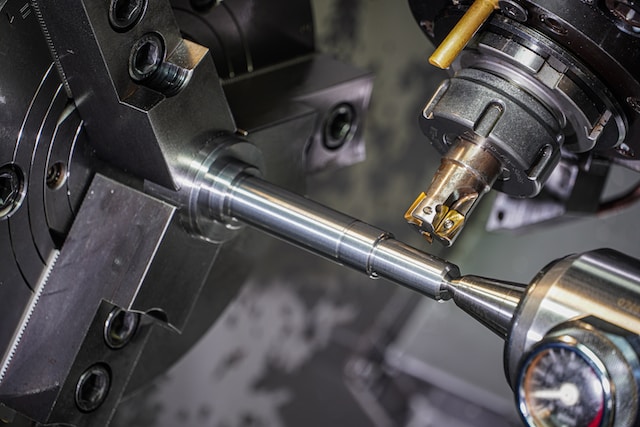

CNC Machining

At VelinxTech, we are proud to offer top-of-the-line CNC milling services as a key component of our comprehensive manufacturing solutions.

Surface Finishing

VelinxTech offers a wide range of surface finishing options, including bead blasting, powder coating, electroplating, polishing, and brushing.

Our Finishing service

Anodizing

Elevate your components with VelinxTech’s precision anodizing service – durability, corrosion resistance, vibrant finishes.

Electroplating

Transform your components with VelinxTech’s electroplating – enhance appearance, protect against corrosion, impeccable metal coatings.

Polishing

Experience the lustrous touch with VelinxTech’s polishing service – mirror-like finishes, impeccable smoothness, unparalleled sheen.

Power coating

Elevate your components with VelinxTech’s powder coating – durable finishes, vibrant colors, enhanced protection, and corrosion resistance.

FAQ

Yes, CNC milling and CNC turning services are well-suited for custom designs and rapid prototyping. VelinxTech’s experienced team can work closely with clients to develop and fabricate customized components to meet specific project needs.

VelinxTech offers a wide range of surface finishing options, including bead blasting, powder coating, electroplating, polishing, and brushing. These finishes enhance the appearance and performance of the final products.

Both CNC milling and CNC turning can handle a wide range of materials, including metals such as steel, stainless steel, aluminum, brass, and more. Additionally, various plastics, including nylon, PE, POM, PP, and ABS, can be processed using these methods.

Yes, CNC milling and CNC turning can be combined to manufacture complex components with diverse features. This combination, often known as multi-axis machining, allows for the creation of intricate parts in a single setup, optimizing efficiency and accuracy.

The duration of a CNC milling or CNC turning project depends on several factors, including the complexity of the part, the quantity required, and the material used. VelinxTech’s streamlined processes and state-of-the-art equipment ensure fast turnaround times without compromising quality.